July 2008 Technology Guide

Tech Source Guide | CAD/CAM

CAD/CAM Central

Continued developments into innovative systems, equipment, software, and business models allow labs to invest in the components that best fit their own operations and their client base, including outsourcing all or part of the casework.

To download CAD/CAM charts, click here.

OPEN

3D Systems

ProJet DP 3000

The ProJet DP 3000 3D Production System comprises an optical scanner and the 3D printing unit, which can output as many as 100 single units in a printing cycle. The VisiJet DP 200 wax material features a smooth surface finish, burns out of investments without ash, and can be used in conjunction with traditional laboratory waxes.

803-326-3900

www.3dsystems.com

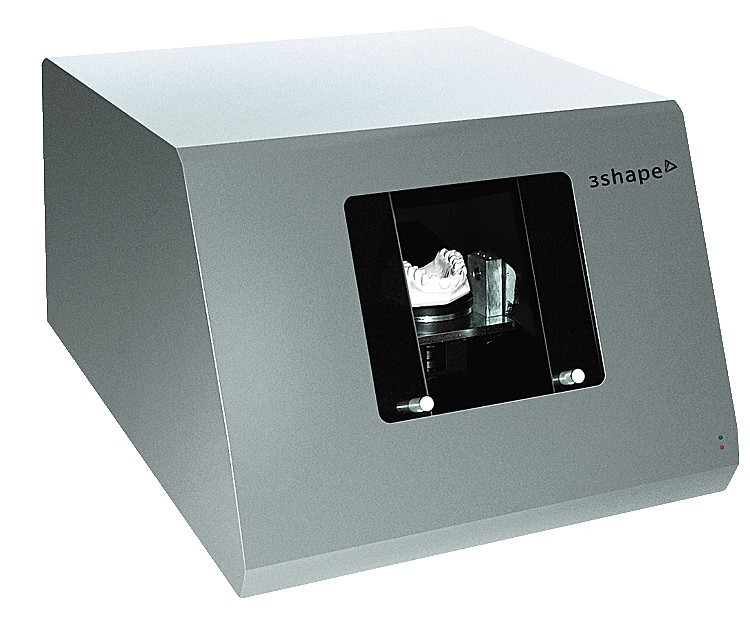

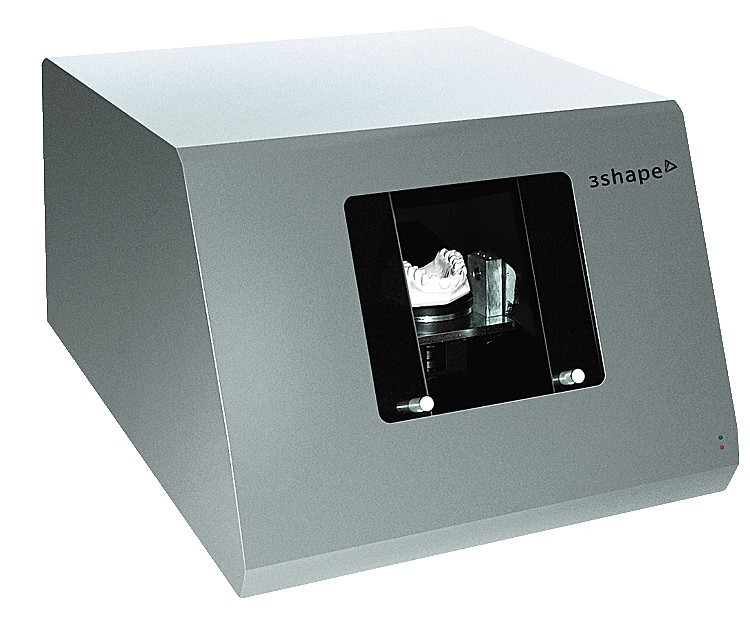

3Shape

D-640

Using advanced optical scanning technology, the D-640 scanner projects thousands of laser planes onto the object being scanned while two high-resolution digital cameras acquire images of the laser line reflections to calculate a precise, fully surfaced 3D model. 3D files can be saved and exported in a number of standard formats, such as STL.

info@3Shape.com

www.3Shape.com

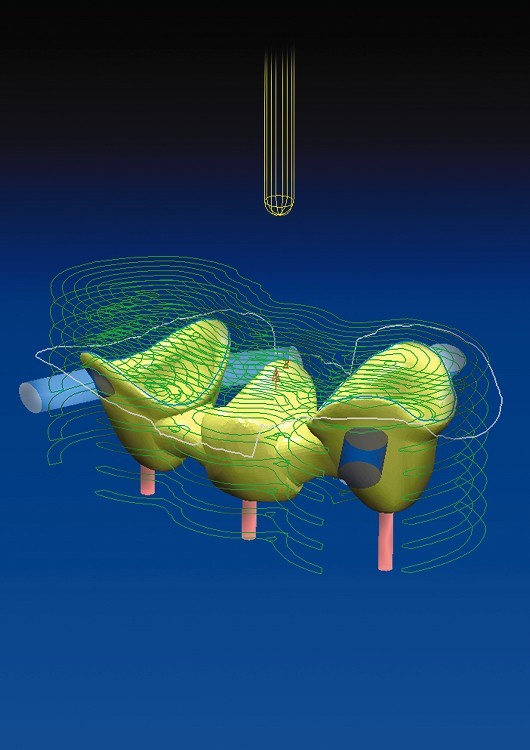

Delcam

DentMILL

DentMILL stand-alone software solution interfaces directly with all industry-standard dental design software, scanners, and milling units for creating crowns, bridges, and partial and full implant bridges in titanium and ceramics. Available later this year, the DentCAD design module will work with the DentMILL open software for a complete dental CAD/CAM package.

888-393-6455

www.delcam.com  EOS

EOS

EOSINT M270

Using Direct Metal Laser Sintering technology, the EOSint M270 rapid prototype printing system laser-sinters batches of CoCr single units, bridge frameworks up to 6 units, implant abutments, and partial denture frameworks. The unit can print 400 to 500 units a day and is available as an in-house option or through a centralized outsource center.

248-306-0143

www.eos.info  Geomagic

Geomagic

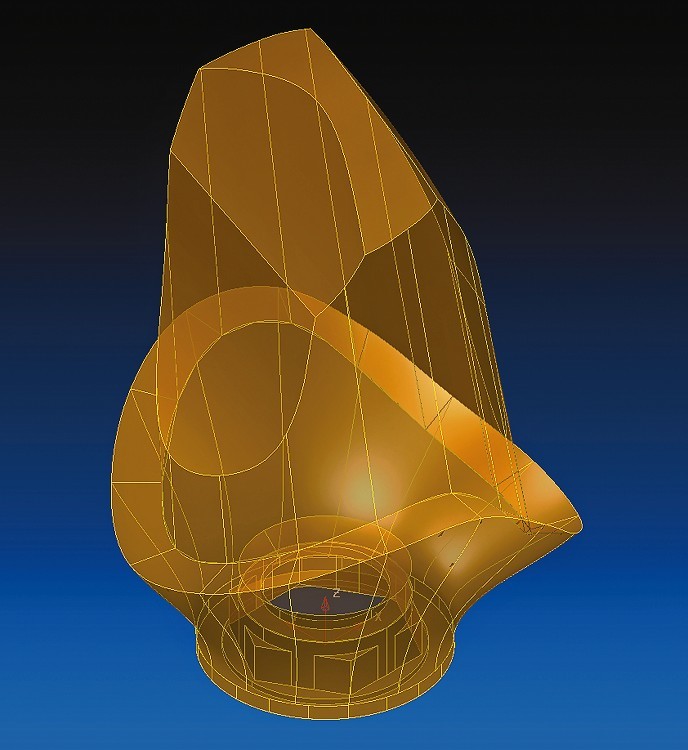

Piano

Based on Geomagic’s agile platform, the robust, automated, and customizable Piano software provides an open interface with all 3D scanning, milling, waxing, and rapid prototyping systems. The module is the first of a series of software solutions for CAD/CAM, virtual work models, custom implant abutment design, and digital full-contour restorations.

919-474-0122

www.geomagic.com  SensAble Technologies

SensAble Technologies

SensAble Dental Lab System

Comprised of a 3D optical scanner, 3D wax printer, and a PHANTOM Desktop 3D “touch” interface, the SensAble system offers a natural and intuitive transition from existing waxup skills to a digital format. It integrates scanning, designing, and fabricating single units, bridges, wax/resin models, and partial denture frameworks.

781-939-7457

www.sensabledental.com

imagen

RX-D

The RX-D 3D metal printer digitally manufactures copings and bridges from CAD-produced virtual waxings generated from 3D scans. The printer freeform fabricates copings and bridges by layering high-noble alloy powders (87% gold imagenBright, 67% gold imagenNatural); once printed, the units are infiltrated and finished. The system can produce up to 200 units per day.

877-773-9663

www.x1-imagen.com

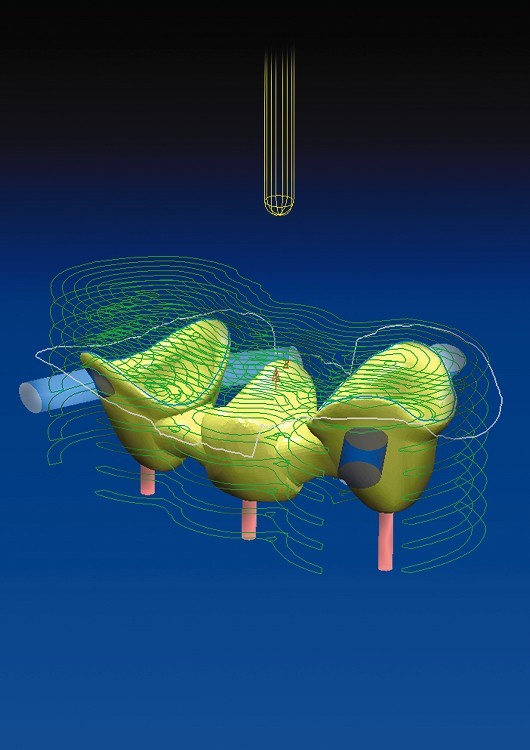

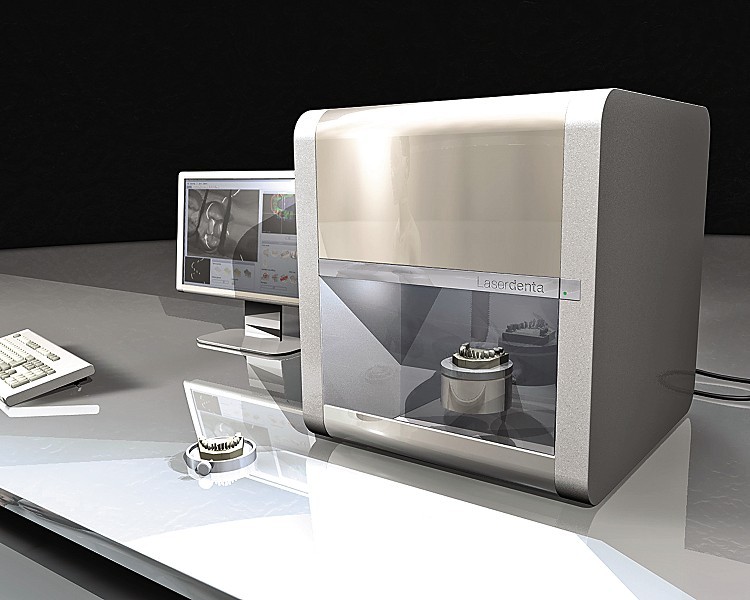

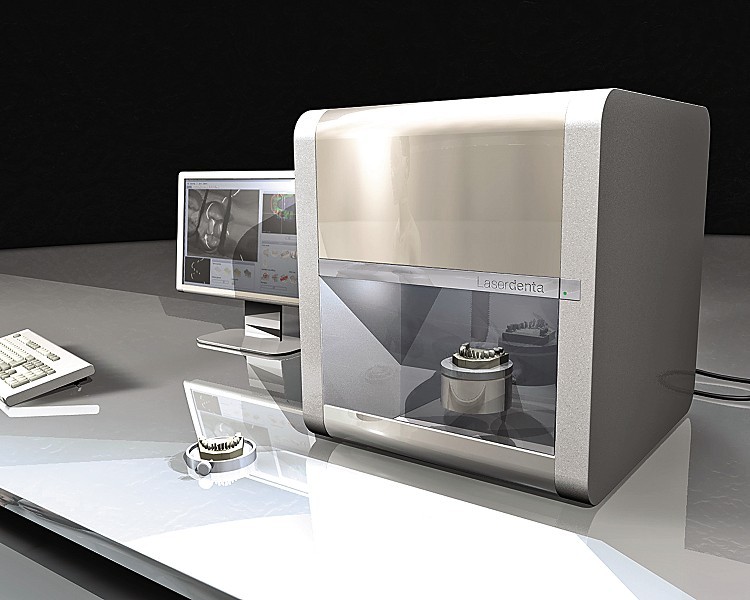

Open Laser Systems

Laserdenta OpenScan

The OpenScan 5-axis laser line scanner handles single dies in 90 seconds to a full arch in 7 to 15 minutes. OpenCAD design software designs waxups, copings, anatomical and full-coverage crowns, bridges, custom implant abutments, and surgical guides. Output can be to any STL-compatible 3D printer, CAD/CAM milling system, or outsource center.

781-297-3552

www.openlaser.com

Schütz Dental Group

TiZian CAD/CAM

The TiZian CAD/CAM system comprises the TiZian Scan 3D white light optical scanner, TiZian Creative design software, TiZian Mill 4-axis milling unit, and TiZian Sintering Oven furnace. The system uses the same milling block system as its sister TiZian Mill non-CAD/CAM milling unit, which allows colorization of zirconia frameworks before sintering.

866-922-1484

www.schuetz-dental.com  Zahn Dental

Zahn Dental

Envisiontec DDP

Creating physical wax/resin patterns from virtual 3D designs, the Envisiontec DDP rapid prototype 3D printer fabricates single copings, bridges up to 4 units, inlays/onlays, full-coverage crowns, veneers, and wax/resin models using Digital Light Processing technology. Castable single wax forms can be printed in approximately 2 hours.

800-496-9500

www.zahndental.com  Evirsa Inc.

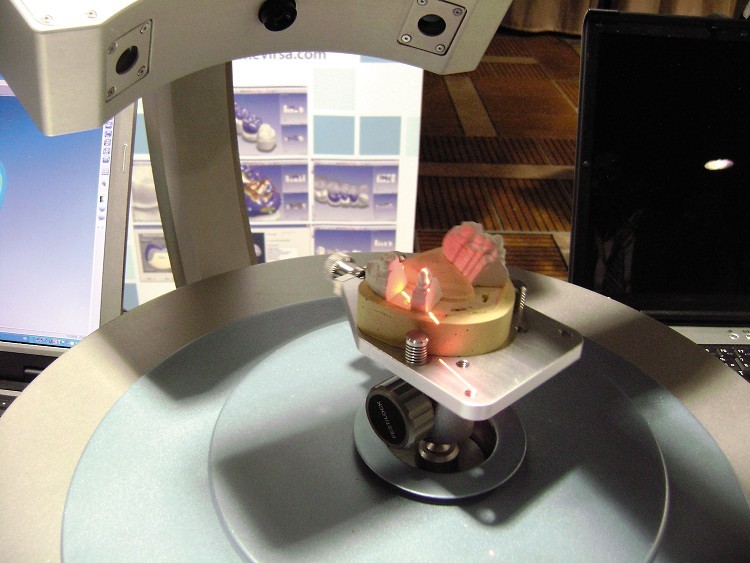

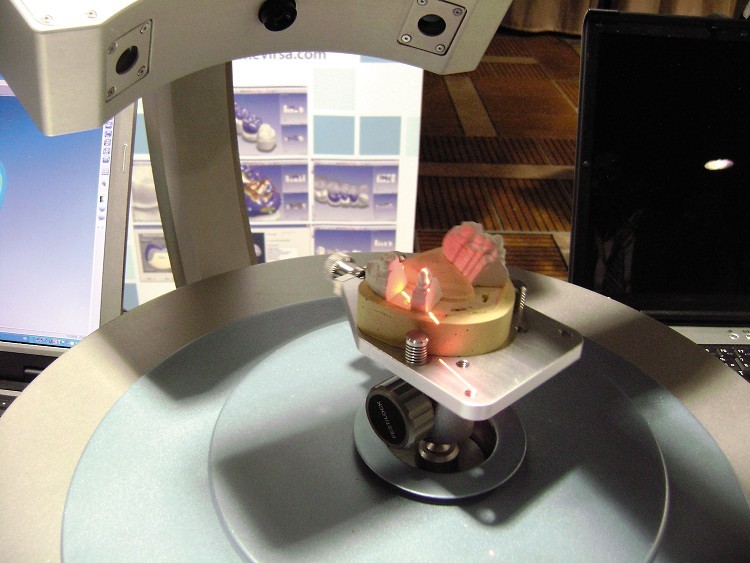

Evirsa Inc.

NEO Open Dental CAD

The NEO Open Dental CAD software suite integrates with STL digital scanners, CNC milling machines, and rapid prototype manufacturing equipment. The NEO Frameworks Design software module affords design control; STL files are then sent to a production center. The NEO Anatomy Design module has a high-resolution library for designing press or cast forms.

514-462-1915

www.evirsa.com

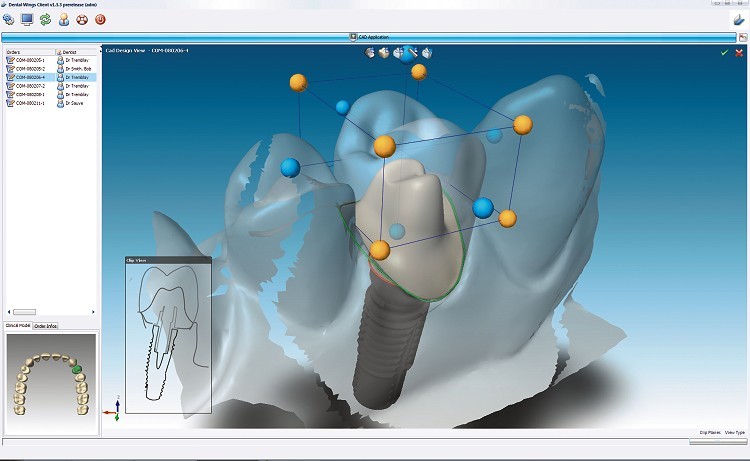

Zahn Dental

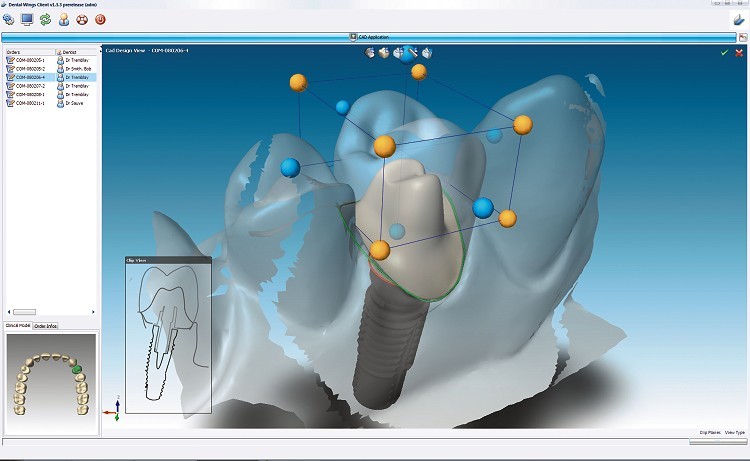

Dental Wings DWOS

Offering closed integration security, the DWOS Dental Wings Operating System platform is built to specifications for the Dental Wings Dental Wings Scanner and Noritake Katana, Wieland Zeno, and Envisiontec systems. The scanner lets users design implants and implant abutments with customized emergence profile and anatomy support.

800-496-9500

www.zahndental.com

Digital Dental Lab

DentalMill

The Digital Dental Lab CAD/CAM system unites scanning and design software from 3shape, DentMILL CAM software, and the DentalMill milling machine. The DentalMill milling unit comes with an automatic tool measurement, integrated vacuum system, three-button PC interface, touch-screen monitor, and 10-position tool changer.

949-395-3613

www.digitaldentallab.com

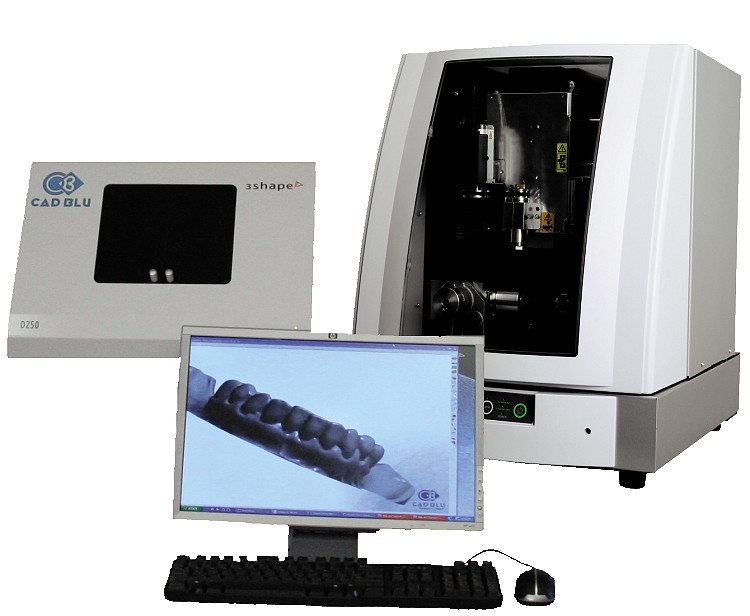

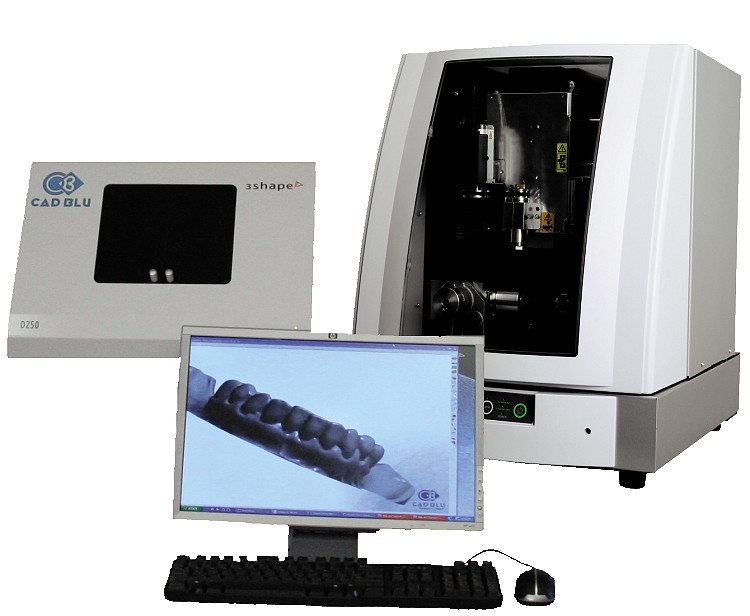

CAD BLU

CAD BLU Restoration System

The CAD BLU Restoration System features the MDX-40ATC wax milling unit, which is capable of milling a single coping in less than 6 minutes using a 98-mm wax disk. The 4-axis milling unit produces a single unit in 15 minutes for a total per-day output of 25 single units, 16 three-unit bridges, and 45 single wax/resin forms.

212-481-8700

www.cadblu.com CLOSED

3M ESPE

LAVA Precision Solutions

By partnering with select digital manufacturers, 3M’s new “selectively open” architecture initiative will provide Lava investors with a wider range of services from 3D model printing to milling full-coverage crowns and custom implant abutments. Three business models provide lab owners with flexible entry into CAD/CAM technology.

800-634-2249

www.3MESPE.com/lava  Sirona Dental

Sirona Dental

Sirona inLab

The inLab CAD/CAM system comprises a scanning/milling unit with built-in design software or a stand-alone inEOS scanner for use with the integrated scan/mill unit or with the dedicated inLab MC XL milling unit. Labs registered with the CEREC Connect portal also can receive digital impression data for in-house or outsource production.

866-INLAB-4U

www.inlab.com  Dentsply Prosthetics

Dentsply Prosthetics

Cercon

Comprised of the Cercon Eye scanner, Cercon Art CAD design software, Cercon Brain milling unit, and Cercon Heat sintering furnace, the Cercon CAD/CAM system offers three business models, all of which center on investing in the Cercon Eye scanner/design software for in-house or outsource production of restoration structures.

800-877-0020

www.allceramiccrowns.com

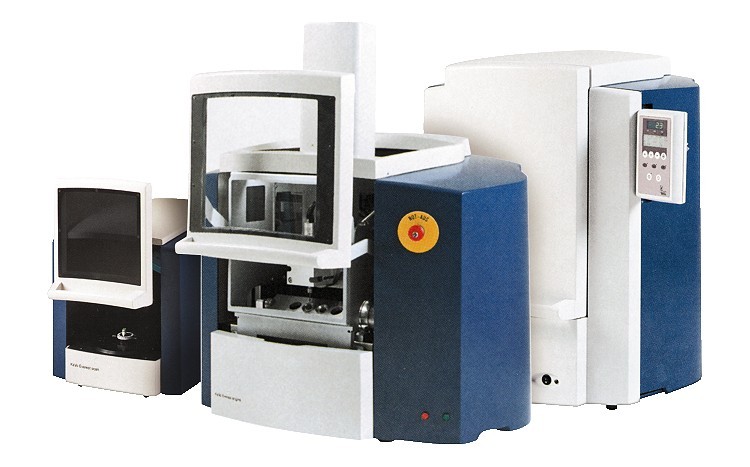

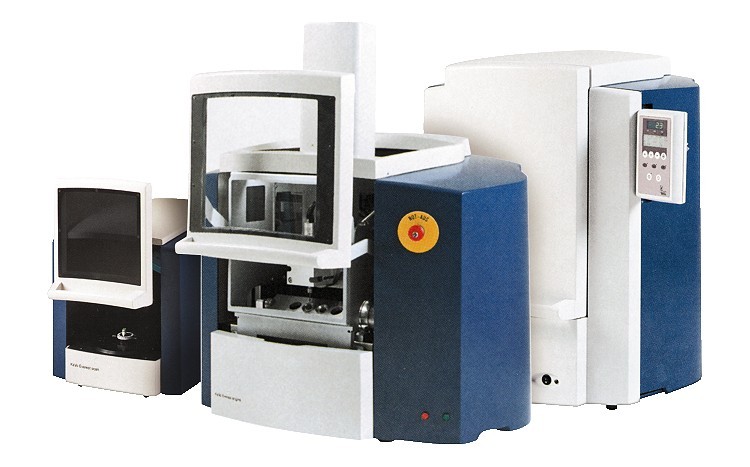

KaVo Dental

EVEREST

An economical entry-level option for high-production laboratories, the 4-axis EVEREST Base Camp milling unit is upgradable to the larger 5-axis EVEREST miller. The system also includes the EVEREST Scan Pro 3D white stripelight optical scanner and second-generation software with the ability to design custom implant abutments.

888-275-5286

www.kavo-everest.com

Wieland Dental

Zeno

The Zeno 2100, 4030 M1, and 4820 M1 CAD/CAM units mill single units, full-coverage crowns, wax/resin forms and models, bridges up to 14 units, veneers, inlays/onlays, and implant abutments. The primary difference is production capacity: The 2100 mills 50 units a day; the 4030 M1, 80 to 100 units a day; and the 4820 M1, 120 units per day.

866-876-0885

www.wieland-dental.de

Zirkonzahn

5-tec

The 5-tec system comprises a 3D white light optical scanner, design software, 5-axis milling unit, and sintering furnace. The system scans and mills single units, bridges up to 14 units, and full-coverage crowns as well as wax/resin patterns and models in a range of materials including pre-sintered zirconia, In-Ceram, ceramic, and resin/wax.

800-989-8931

www.zirkonzahn.com OUTSOURCE OPEN

Custom Milling Center

CMC offers the open-architecture Dental Wings scanner with new Dental Wings Operating System. Design data generated by the DWOS is compatible with the Nortitake Katana and Wieland Zeno milling units or with the Envisiontec DDP 3D wax rapid prototyping system. CMC also offers similar business model options for the HintEls scanning and milling technology.

877-933-6455

www.custom-milling.com  Dale Dental

Dale Dental

Among Dale Dental’s closed- and open-architecture offerings offered exclusively to labs are understructures for Captek, Cercon, Empress, Etkon, EVEREST, In-Ceram, Katana, Lava, PFM copings, Procera, and WolCeram as well as BioCad one-piece, titanium CAD/CAM implant bars and CAD/CAM custom abutments for a wide range of platforms in both titanium and zirconia.

888-GET-DALE

www.DaleDental.com

Cynovad Inc.

Ovaline

In addition to sending models or single dies to the centralized outsource center for scan, design, mill, and sinter, labs can purchase the open-architecture 3D laser optical white light OvaScan or i3 Evolution scanners and send data electronically to the milling center or purchase all system components for complete control over all phases of production.

514-337-1444 Ext. 365

www.cynovad.com

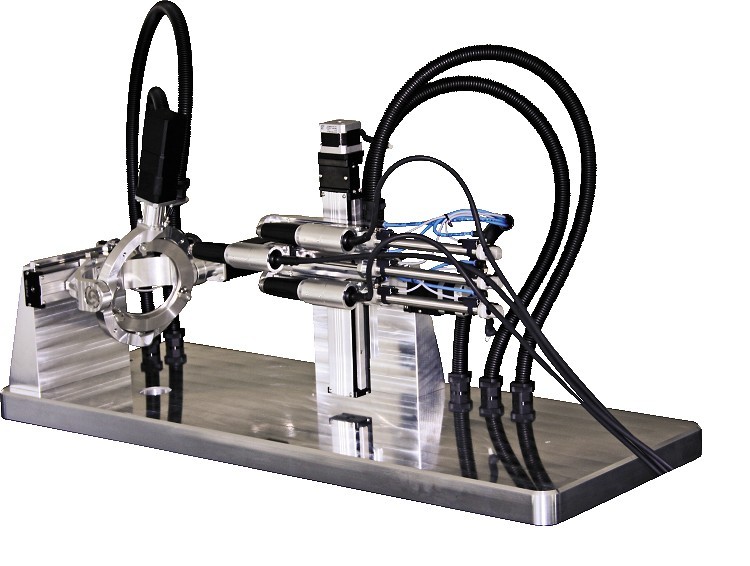

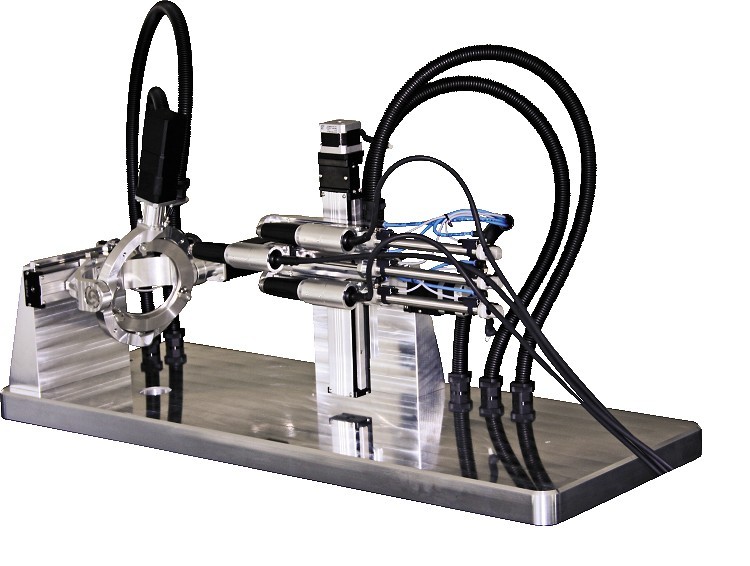

Espritdent

The Espritdent centralized outsourcing center combines the Elite multi-axis motion scanner system and design software that incorporates automatic margin line detection, removes undercuts, and provides extensive on-screen waxing capabilities with manufacturing capacities. Alternatively, labs can send models to the center for scan, design, and mill services.

877-832-0217

www.espritdent.com  Glidewell Direct

Glidewell Direct

Prismatik Clinical Zirconia

Glidewell allows laboratory outsource customers to send single dies or models for the scan, design, and milling processes, to become a Prismatik CZ Remote Design Center with in-house control over the scan/design process, or to purchase the entire system including scanner with design software, milling unit, and sintering furnace.

888-303-6470

www.glidewelldirect.com

Laboratory Solutions

Offering 3M ESPE Lava, Sirona Cerec inLab, Nobel Biocare Procera, Wieland Zeno, Ivoclar IPS e.max, Glidewell Prismatik CZ, and Kavo EVEREST, Laboratory Solutions mills zirconia crown copings and bridge frameworks and provides labs with specialized training. The center also offers Captek, composite restorative solutions, full-contour wax patterns as well as custom implant abutments in titanium and zirconia.

800-468-3319

www.nilabsolutions.com  Preat Corp.

Preat Corp.

ISUS Design & Milling Center

ISUS allows labs to send cases to the center for scanning, framework design, and fabrication, or they can use an open-architecture scanner for in-house scan/design and send data to the center for milling of custom implant bridges to 14 units, implant bars, bars with attachments, implant abutments, and hybrid cases from zirconia, titanium, non-precious metal, or ceramic.

800-232-7732

www.preat.com  U-Best Dental Technology

U-Best Dental Technology

TDS Milling Center

Cut and trimmed models of single dies can be sent to TDS Milling Center for scan, design, and milling, or labs can use an open-architecture scanner and send design data to TDS for milling. TDS offers 5-axis milling from singles to up to 14 units and cover from coping, crown, veneers, and inlay/onlay in presintered zircornia.

866-686-1899

www.ubestdental.com

Sun Dental Labs

Suntech

Through the Suntech outsource center, laboratories can send dies or models for scanning, design, milling, and sintering, or they can purchase a 3Shape scanner and send design data electronically to the milling center for the fabrication of single copings, bridges up to 16 units, full-coverage crowns, and custom implant abutments as well as wax/resin forms.

866-561-9777

www.suntechdental.com

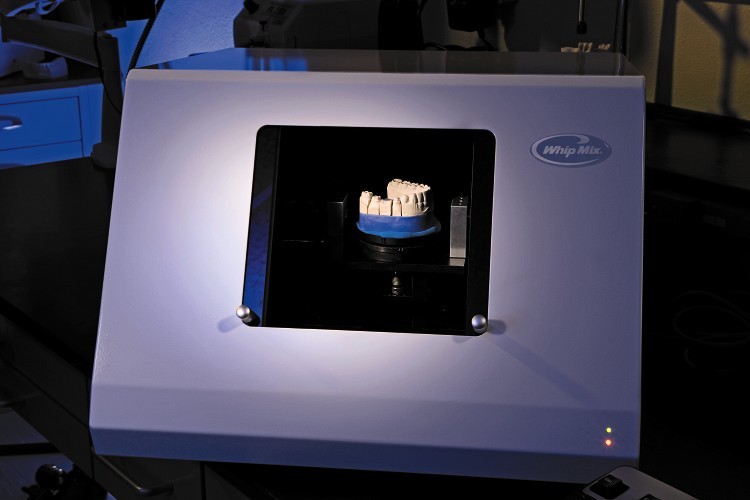

Whip Mix

Vericore

In addition to full-service outsourcing, the Vericore outsource center offers labs the option to purchase the 3D laser/optical scanner with design software and send scan/design data to the center electronically. Vericore offers 5-axis milling of single-unit copings and bridges to 14 units in cold isostatically pressed Metoxit zirconia.

866-301-9801

www.whipmix.com OUTSOURCE CLOSED

3M ESPE

Authorized Lava Milling Centers (ALMCs)

Complete outsourcing to ALMCs allows labs to offer Lava restorations without investing in hardware or software. In becoming an Authorized Lava Design Center (ALDC), labs purchase the Lava Scan ST Design System to scan and design substructures and send the file electronically to an ALMC for milling and sintering.

800-634-2249

www.3MESPE.com/lava

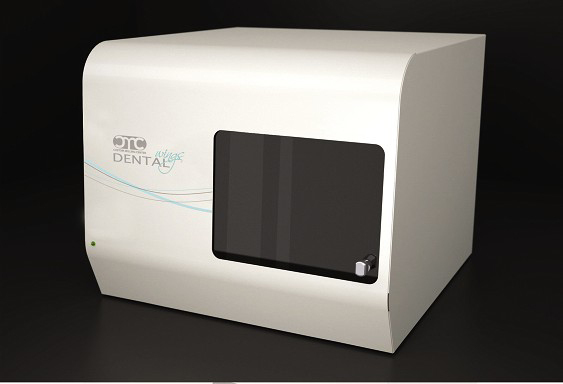

Cyrtina Center Inc.

Cyrtina CAD/CAM

The Cyrtina outsource center offers a variety of services for purchasers of the Cyrtina 3D laser scanner with CyrtinaCAD design software, including single units, full-coverage crowns, bridges up to 7 units, inlays/onlays, custom implant abutments, and veneers in BioZyram zirconia or ceramic as well as wax/resin models and CyrtinaGuide surgical implant guides.

425-765-9400

www.cyrtina.nl  Dentsply

Dentsply

Compartis

Established exclusively for users of the Cercon Eye scanner and Cercon Art CAD, Compartis USA’s centralized outsource center provides the flexibility to optimize the framework design in-house and send the scan data electronically to the center for milling zirconia single units and bridges up to 9 units or wax/resin forms for pressing or casting.

800-877-0020

www.allceramiccrowns.com  Nobel Biocare

Nobel Biocare

Procera

Integrating CAD/CAM technology with industrial production, the Procera system delivers single units, bridges up to 14 units, veneers, implant abutments, and the Procera Implant Bridge in zirconia, alumina, or titanium. Labs use the Piccolo or Forte (pictured) scanner for in-house control of the scan/design process and send design data to the production facility.

800-993-8100

www.nobelbiocare.com  Sirona Dental

Sirona Dental

infiniDent

Exclusively for Sirona inLab and inEos users, the infiniDent production center enables users to expand services via a rapidly growing menu of materials and indications. Users upload digitally scanned framework designs to the infiniDent fabrication center for milling, laser sintering, or 3D printing of substructures in a wide range of materials.

800-659-5977

www.infinident.com  Straumann USA

Straumann USA

Etkon

The Etkon/Straumann outsource center revolves around purchase or lease of the es1 scanner, which handles single dies, full-arch models, waxups, cut and trimmed models, implant abutments, and bite registrations for milling single units, full-coverage crowns, bridges, veneers, inlays/onlays, implant abutments, and wax forms.

817-701-1181

www.etkonusa.com  Amann Girrbach

Amann Girrbach

Ceramill

The compact Ceramill Base System milling unit produces high-precision zirconia frameworks for crowns and bridges in-house quickly and easily via the pantograph principle to transfer forms via a combination of an interconnected probe head and milling head. Using a process similar to modeling with wax, it requires no special technical knowledge.

800-851-3719

www.amanngirrbach.com

GlobaLink Solutions Dental

GlobaLink Solutions Dental

ELC-One

Suited for a smaller lab operation, the ELC-One system uses an ELC electrophoretic deposition process to place particles of VITA In-Ceram alumina/zirconia material on a master die, resulting in single copings and 3-unit bridge substructures. It offers easy operation with fast setup and breakdown and a quick return on investment.

877-446-6475

www.glsdental.com  Zirkonzahn USA

Zirkonzahn USA

Zirkograph ECO

The Zirkograph ECO copymill unit produces single copings, bridges up to 16 units, inlays/onlays, full-coverage crowns, and implant abutments from presintered zirconia blocks, ceramic, or resin/wax materials. A spring carrier facilitates use, LED lamps light the workspace, and a two-duct air connection provides effective suction.

800-989-8931

www.zirkonzahn.com

Schütz Dental Group

TiZian Mill

Described as easy to learn and operate, the TiZian Mill copymilling unit produces frameworks for single copings, bridges up to 16 units, and implant abutments out of pre-sintered TiZian zirconia milling blocks in six different shades. Milling takes just 15 minutes per unit. The device compensates for sintering shrinkage during the milling process.

866-922-1484

www.sdginnovations.com  Zahn Dental

Zahn Dental

C. Hafner

The economical C. Hafner CeHa ECS unit employs an electrophoretic deposition process to deposit ceramic particles onto a die, creating a VITA In-Ceram alumina framework in less than 2 minutes. Ceramic slurry is premixed and transferred to the unit, then the die is submerged into the slurry and withdrawn, creating the coping.

800-496-9500

www.zahndental.com

Schick Dental

Z-System

The compact, economical Z-System zirconia copymilling unit uses C3 motor technology with a high-precision, high-torque chuck for smooth operation; it integrates the touch spindle and milling spindle side-by-side on the same arm. It also includes a blow-out hose, proprietary LED lighting integrated into the spindles, and an integrated armrest.

800-921-3177

www.schickdentalusa.com

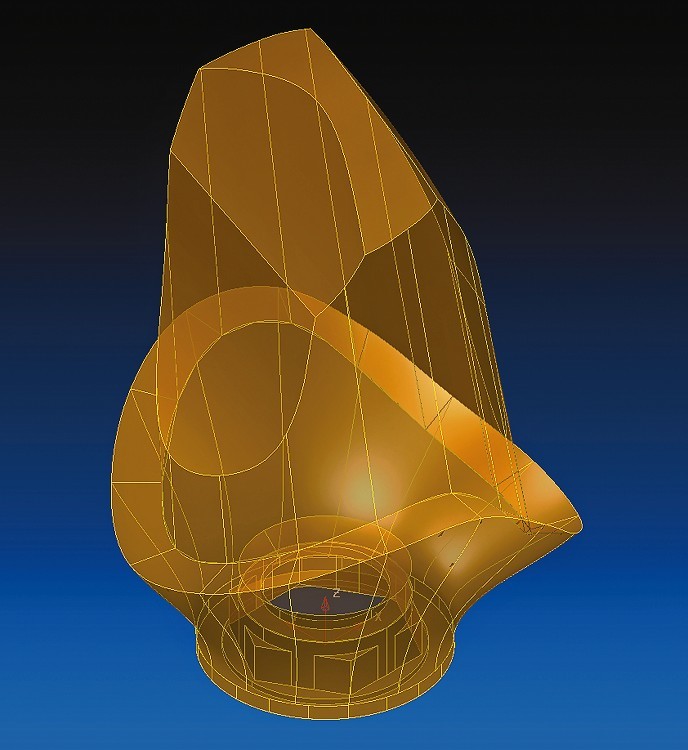

Atlantis Components Inc.

Patient-Specific Abutments

Atlantis Components accepts either data from a scanned dental model created from an implant-level impression and sent to the company by the laboratory or from CAT scan digital information. The data is fed into the company’s powerful 3D computer software for abutment design. Compatible with 90% of the implant systems on the market in the United States, the software designs the optimal abutment to fit the edentulous space, and transmits the design information to a milling unit that creates the patient-specific titanium or zirconia custom abutment. Individual preferences also can be incorporated into the software design. Model work along with the completed abutment is returned to the lab for crown fabrication within two to three days of receipt.

877-828-5268

www.atlantiscomp.com

BIOMET 3i

ARCHITECT PSR ENCODE SYSTEM

The Encode healing abutment indicates the level of an implant in relation to the soft tissue and bone, healing abutment dimensions, and hex orientation. A supragingival impression with the healing abutment is sent to the lab where the model is poured, sectioned, and pinned. The articulated case is returned for scanning, virtual abutment design, and milling from titanium for external-hex implant systems and for internal-hex Certain implants as well as titanium bars.

800-342-5454

www.biomet3i.com

EOS

EOS Geomagic

Geomagic SensAble Technologies

SensAble Technologies

Zahn Dental

Zahn Dental Evirsa Inc.

Evirsa Inc.

Sirona Dental

Sirona Dental Dentsply Prosthetics

Dentsply Prosthetics

Dale Dental

Dale Dental

Glidewell Direct

Glidewell Direct

Preat Corp.

Preat Corp. U-Best Dental Technology

U-Best Dental Technology

Dentsply

Dentsply Nobel Biocare

Nobel Biocare Sirona Dental

Sirona Dental Straumann USA

Straumann USA Amann Girrbach

Amann Girrbach GlobaLink Solutions Dental

GlobaLink Solutions Dental Zirkonzahn USA

Zirkonzahn USA

Zahn Dental

Zahn Dental